The Energy Management System (FEMS) utilizes modern computer and distributed control technologies to establish a comprehensive energy consumption management platform within factories. It enables the categorized monitoring and management of energy consumpt

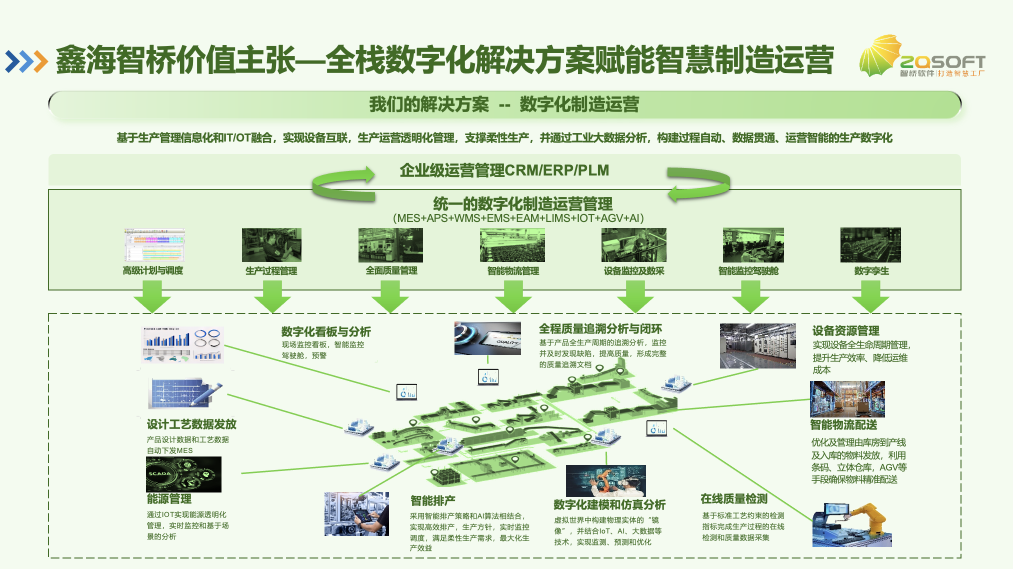

With the increasing popularity of intelligent manufacturing and MES systems, many cutting-edge manufacturing enterprises have put forward higher requirements for MES. They do not meet the traditional MES system's model of document flow and manual recordin

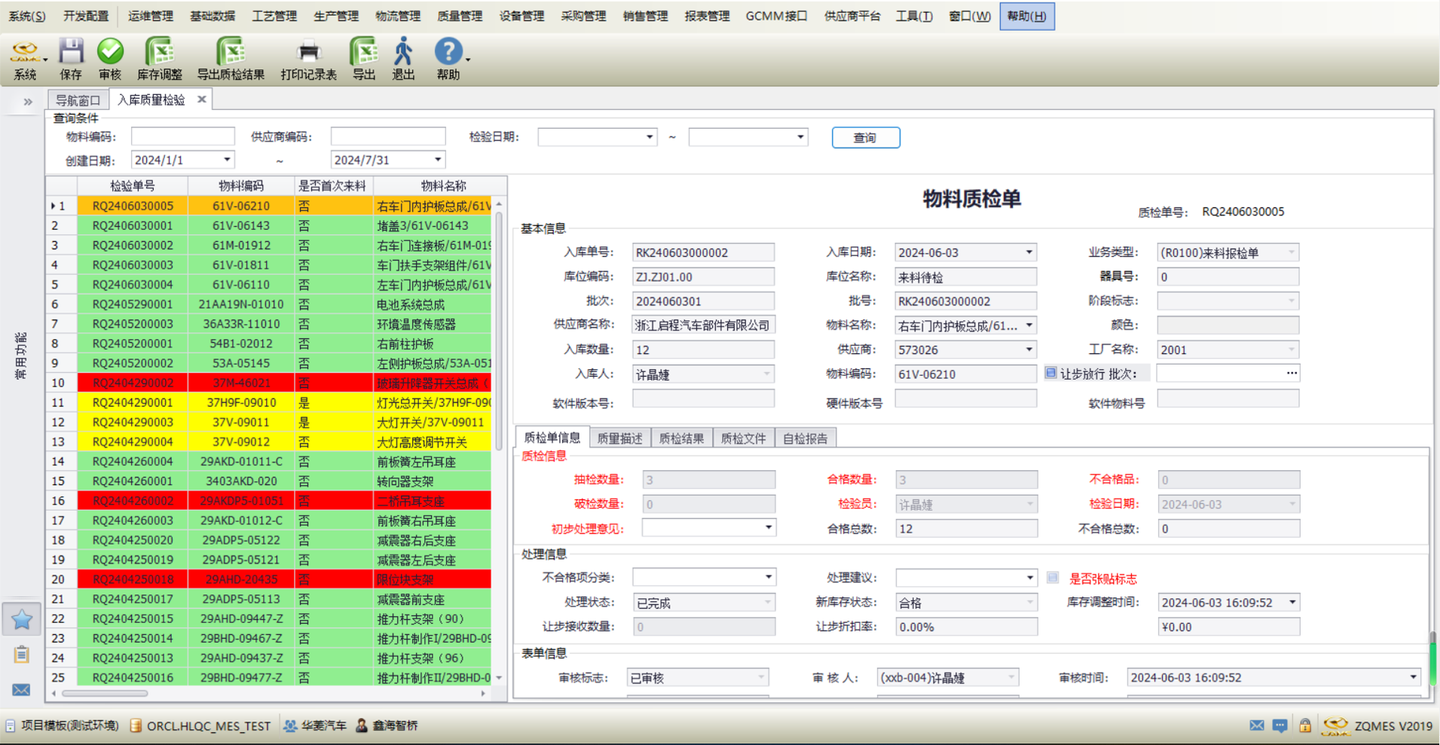

In the production chain of manufacturing, the quality of raw materials is the cornerstone that determines the final product quality, and incoming inspection is the core means of controlling this critical link. The Quality Management System (QMS), with its

ZQSOFT has been deeply engaged in tire manufacturing for many years, and has tailored intelligent manufacturing system solutions for many tire enterprises in Vietnam, Thailand, Morocco and other places, covering core modules such as MES, APS, equipment in

MES (Manufacturing Execution System) needs to obtain relevant process, quality, and output data during the production process in order to achieve the goals of digitalization, transparency, and real-time production.

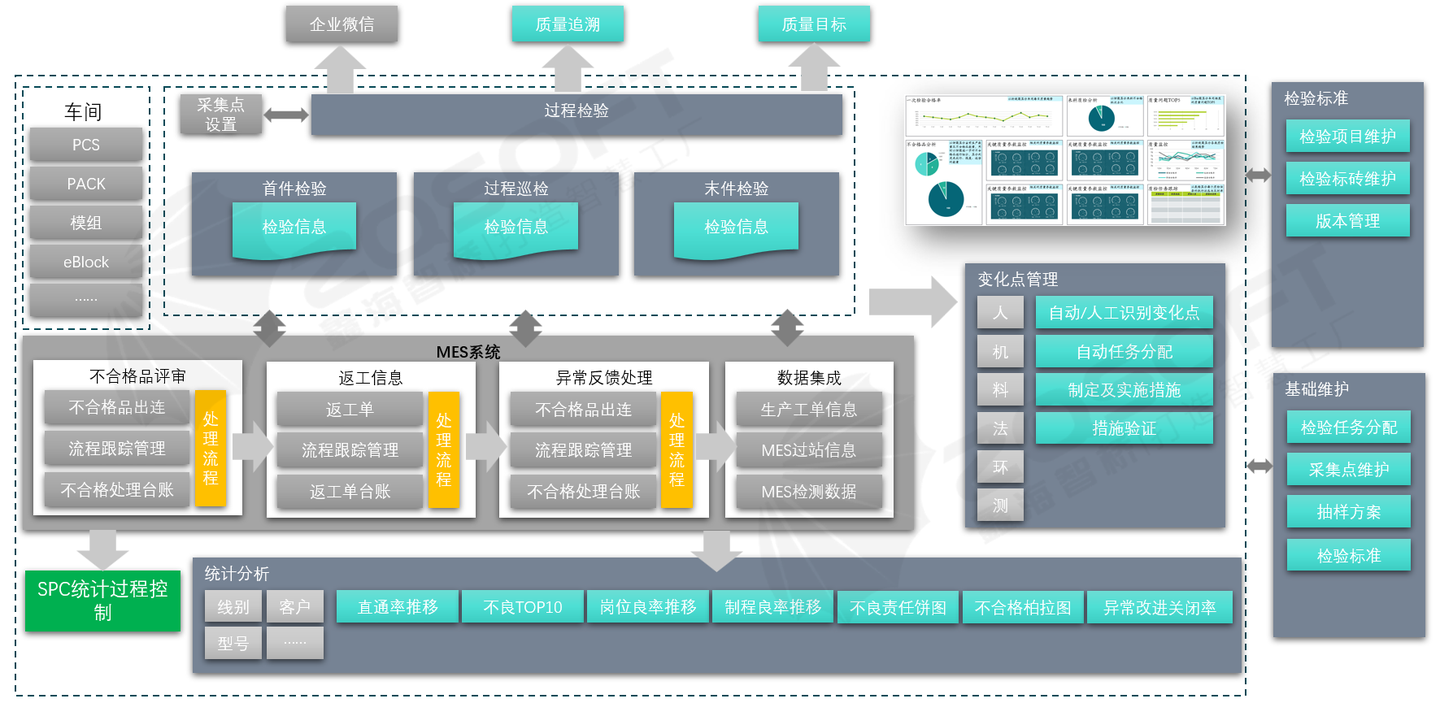

In the current booming development of the new energy industry, the battery assembly industry, as a key link, continues to see an increase in market demand. However, battery products have extremely high requirements for safety, stability, and consistency.

The equipment data acquisition technology of MES (Manufacturing Execution System) is the core link to achieve digitalization and transparency of the production process. Its goal is to obtain real-time and accurate information on equipment operation status

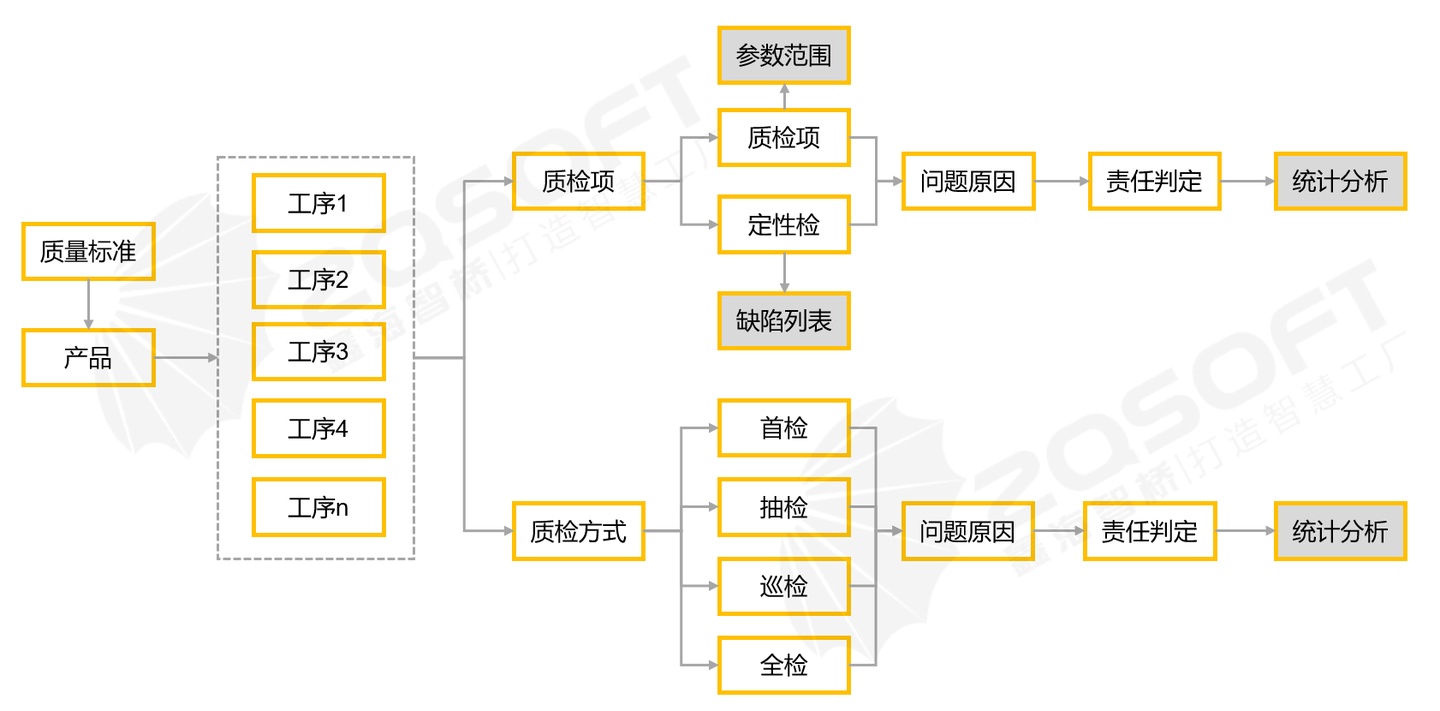

In modern manufacturing, the Manufacturing Execution System (MES) serves as a crucial bridge connecting the enterprise planning layer with the production control layer, playing a pivotal role in achieving process quality control. ZQ-MES conducts comprehen

With the increase in global car ownership and the rapid development of new energy vehicles, the demand for tires in the market will continue to grow. Under the dual pressure of environmental protection requirements and funding, small and medium-sized tire