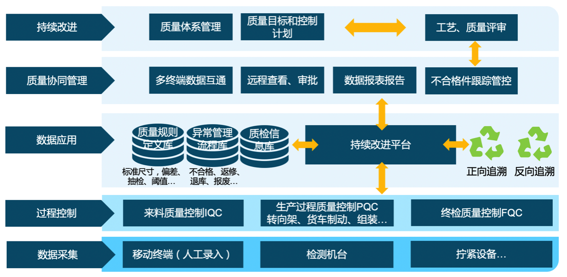

Quality inspection data acquisition

Key parts information collection

Assembly quality information collection (process parameters, quality inspection data)

Quality data traceability

Intelligent picking of raw materials, workshop warehouse and finished product warehouse to reduce part picking errors

RFID WIP and circulation equipment tracking and tracing in production workshop

Through the production site visualization, improve the processing accuracy and timeliness of material supply

Quickly and conveniently generate material pulling information, real-time monitoring of material shortage, improve the timeliness of fed-material distribution

Job plan receiving and displaying

Product sequence and status on the assembly line

Equipment status information display and equipment spot inspection information maintenance

Material bar code acquisition

Lack of material or waste ANDON alarm

Station operator information collection

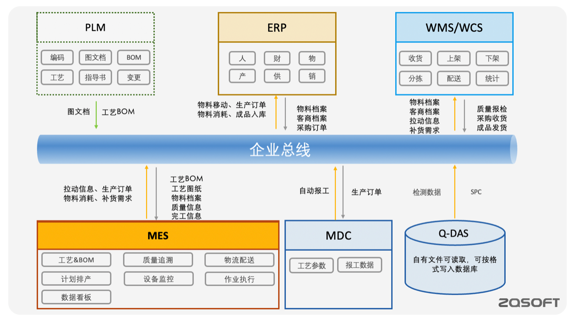

ERP plan receiving and maintenance

Prepare production plan for assembly line and processing line according to resource constraints and configurations

Plan issuance and release

Production plan change management (order insertion, change handling)

Production plan query and export

ERP return on completion

Assembly process personnel, products, assembly parts, assembly quality, assembly equipment processing parameters, equipment status, testing equipment, testing data

Data acquisition mode: bar code, RFID, equipment PLC interface, etc

Data statistics based on production process

Lean production related KPI index analysis: efficiency, output, quality, equipment