The Energy Management System (FEMS) utilizes modern computer and distributed control technologies to establish a comprehensive energy consumption management platform within factories. It enables the categorized monitoring and management of energy consumption for water, electricity, and gas (compressed air, coal gas, natural gas, and steam), helping enterprises achieve cost control and energy efficiency.

Data Collection and Monitoring

Traditional energy management methods rely on manual records and simple measurement, making refined management challenging. By integrating with IoT technologies, sensors, and intelligent instruments, the Energy Management System collects real-time data on various energy sources, building a complete energy database to support precise energy control.

Data Analysis and Optimization

With advanced analytical algorithms, the system processes and analyzes collected data to understand the operational status and performance of the energy system. It provides optimization suggestions and automatically generates energy usage reports, offering visual data analysis to help enterprises develop scientific energy strategies. When integrated with APS and MES systems, it provides low-energy consumption scheduling strategies, optimizing production sequences and reducing energy consumption.

Energy Scheduling and Control

Based on real-time energy demand and system operation, intelligent energy scheduling and control can be achieved to efficiently arrange production execution and save energy.

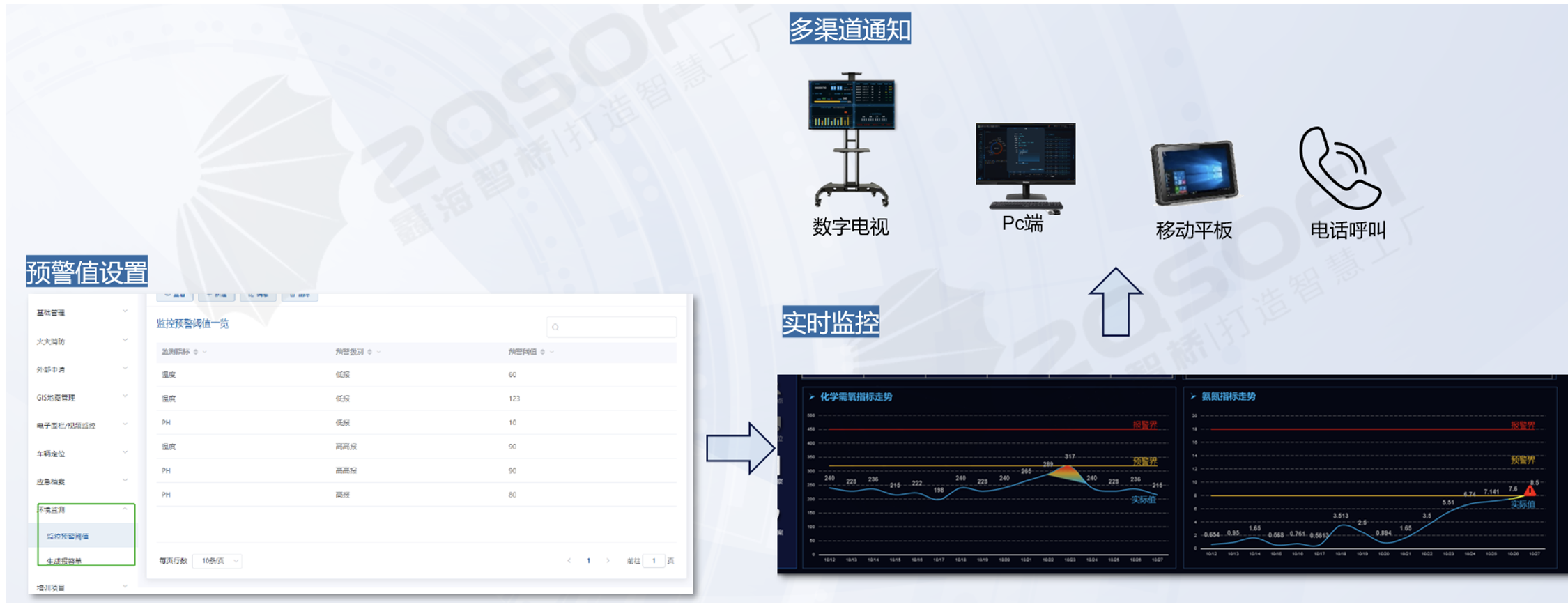

Fault Detection and Exception Warnings

Real-time monitoring and threshold settings help detect energy leaks and anomalies, enabling timely warnings and rapid issue resolution to reduce energy waste.

Core Value of the Energy Management System

•Improving Energy Efficiency: Real-time monitoring and data analysis allow for a precise understanding of energy use, uncovering potential savings and offering optimization suggestions to significantly improve energy efficiency.

•Reducing Operational Costs: Reasonable energy scheduling and control help reduce energy waste and expenses, such as electricity and water costs. Automated data collection and analysis reduce the workload for manual metering and data statistics, cutting labor costs.

•Enhancing Enterprise Competitiveness: In the current low-carbon economy era, energy-saving performance reflects corporate social responsibility and is also a crucial part of market competitiveness. Effective energy management not only lowers costs but also earns enterprises environmental reputation, policy support, and customer preference.

In conclusion, the Energy Management System is a valuable tool for enterprises to achieve energy efficiency, improve economic benefits, and strengthen market competitiveness. In future developments, it will play a more critical role in promoting carbon neutrality and societal progress.

About Xinhai Zhiqiao (Soft Promotion)

In the application of energy management systems, the maturity of technology and solutions determines whether enterprises can truly achieve energy efficiency and cost optimization. Xinhai Zhiqiao has deep expertise in the industrial software field, offering self-developed MES, MOM, and APS systems to provide comprehensive solutions for data collection and energy scheduling, helping enterprises achieve digital and intelligent energy management.

Currently, Xinhai Zhiqiao’s solutions have been successfully implemented by numerous manufacturing enterprises domestically and internationally, not only improving production efficiency but also significantly reducing energy costs. In the future, Xinhai Zhiqiao will continue to drive innovation, providing more efficient and intelligent solutions to help enterprises achieve green transformation and create greater value.