Currently, the traditional tire manufacturing industry is facing the dilemma of high production and circulation costs, low efficiency, and serious resource waste. Faced with fierce competition caused by product homogenization, it is necessary to find better solutions from the perspective of efficiency improvement. The rapid changes in market demand require enterprises to have faster and more agile response capabilities.

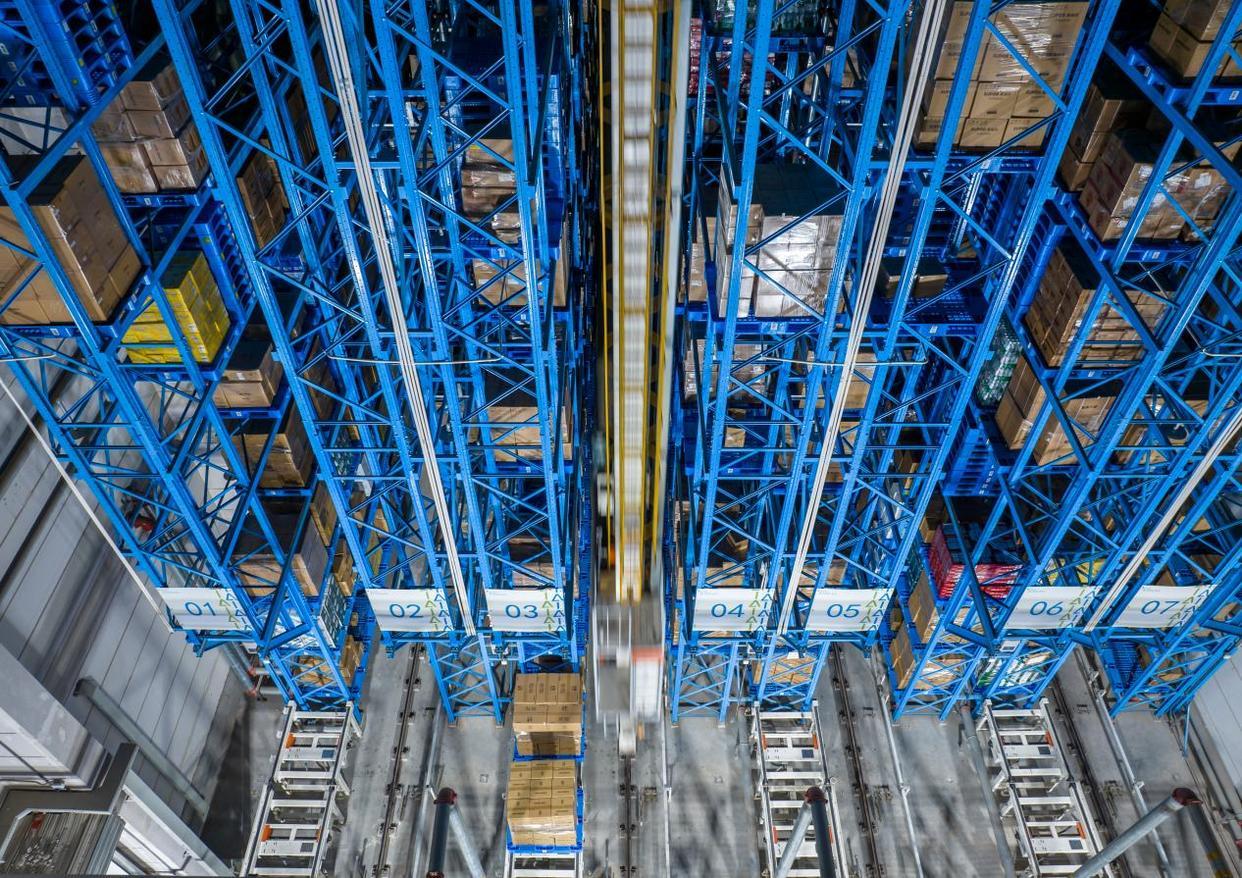

Automated warehousing system integration solutions can better assist enterprises in facing industry changes and challenges.

The automated logistics solutions in the molding and vulcanization workshops involve the use of EMS or conveyor lines to store the formed embryos in the vertical warehouse, the use of conveyor lines to store the embryos out of the warehouse, and the upgrading of EMS/vertical warehouse and vulcanization systems.

In the vulcanization and successful tire quality inspection workshops, the upgrade of automated warehousing and logistics also involves three-dimensional warehouses, stackers, conveyor lines, EMS conveyor systems, WMS/WCS systems, robotic arms, equipment modification, and docking.

In the mixing and semi component workshops, the upgrade of automated warehousing and logistics mainly includes three-dimensional warehouses, AGVs, and chain machine devices; The MES system achieves automatic loading and unloading of production by scheduling AGVs and three-dimensional warehouses, minimizing manual involvement and truly realizing a black light factory.

ZQSOFT believes that the upgrading of automated logistics storage is not only the upgrading of hardware equipment, but also the need for good systems to integrate diversified logistics and storage equipment to achieve the overall optimization of logistics.

The implementation of automated warehousing and logistics projects is not only about improving logistics management, but also about helping enterprises to increase their market response speed and occupy a more advantageous position in future industry competition.

[ZQSOFT, creating new value for customers]

Smart manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing corporate competitiveness. Against this backdrop, ZQSOFT, with its profound technical accumulation and rich industry experience, continues to provide customers with leading IoT technology, smart manufacturing solutions, and MES/MOM/APS systems.

As a technological leader in the industry, ZQSOFT continuously promotes the deep integration of digital transformation and intelligent manufacturing, committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of 'innovation-driven, intelligent manufacturing', helping our customers stand out in the fierce market competition and stay at the forefront of industry development.