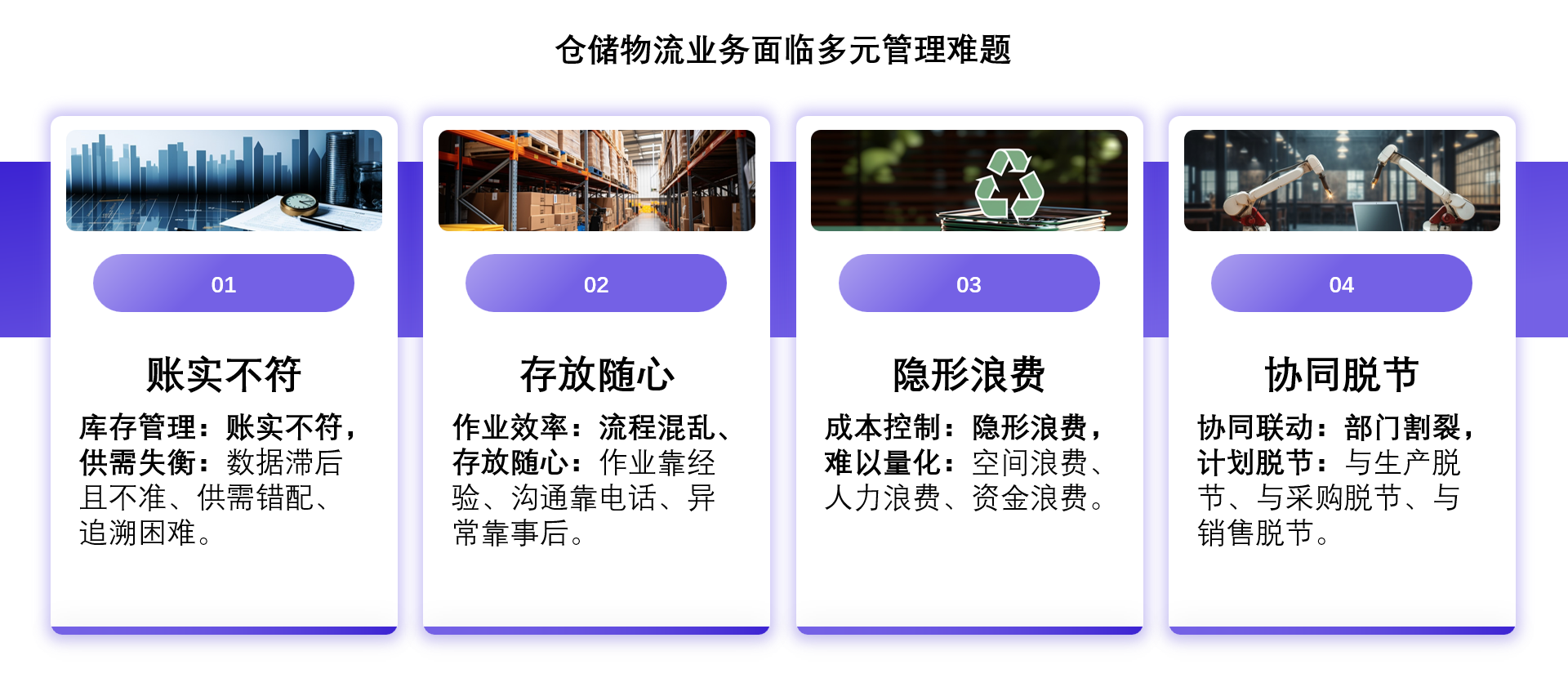

Inventory management: discrepancies between accounts and reality, imbalance between supply and demand. Data is lagging and inaccurate, supply and demand mismatch, and traceability is difficult.

Operational efficiency: chaotic processes, haphazard storage. Operations rely on experience, communication relies on phone calls, and anomalies are addressed after the fact.

Cost control: Hidden waste, difficult to quantify. Waste of space, waste of manpower, waste of funds.

Collaboration and coordination: Departments are fragmented, plans are disconnected. They are disconnected from production, procurement, and sales.

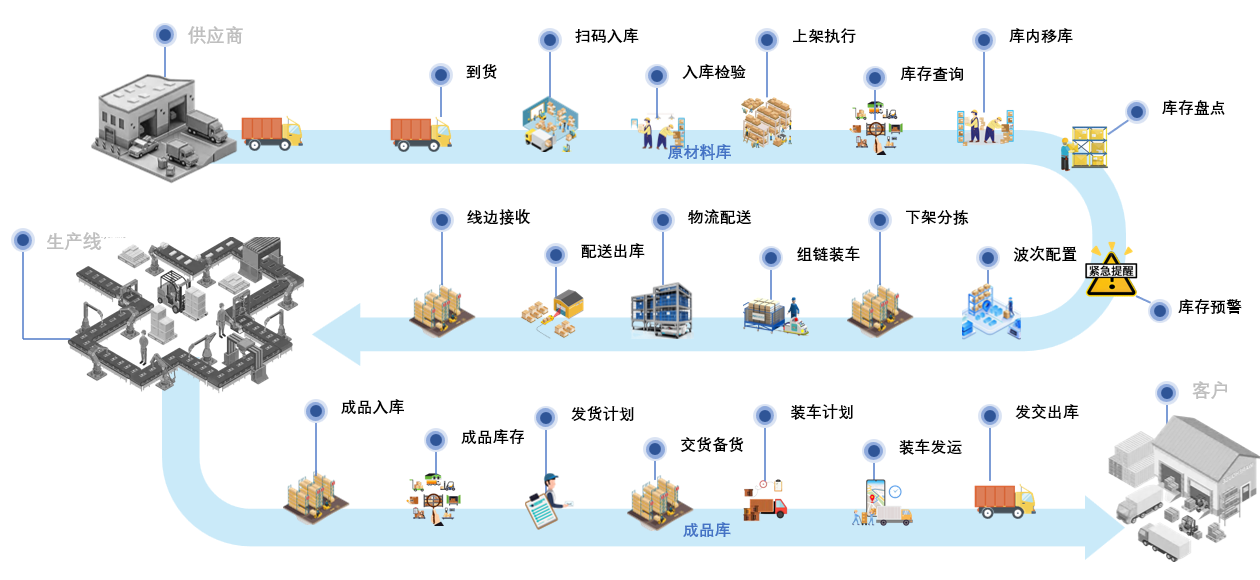

Integrate digital means to solve problems in the entire warehouse business scenario, using tags/RFID as the information carrier to control the entire warehouse logistics process from supplier arrival, warehousing, shelving, quality inspection, inventory, sorting, chain assembly, distribution, and ex-warehouse;

Build a full-stack management system featuring "business-driven tasks, task command and execution, and execution feedback and monitoring";

Address the traditional warehouse industry's human-centric management model;

Achieve intelligent and transparent management of the entire warehousing and logistics process.

In the past: Faced with ambiguous plans from department heads, data with mutual accusations, and a cluttered Excel screen, I felt overwhelmed and at a loss.

Now: By opening the WMS real-time data dashboard on the computer and analyzing core data, we can further compress the production cycle and optimize future procurement based on the existing inventory. This clear arrangement gives us more confidence and certainty in planning the future of warehousing.

In the past: Faced with the production manager's inquiries about material requests, the financial supervisor's concerns about discrepancies between accounts and reality, and the sales director's questions about finished product delivery schedules, the warehouse supervisor could only rely on Excel files and communication records in the computer to conduct individual inquiries and provide frantic feedback.

Now: The warehouse supervisor confidently meets the requirements of various department heads with precision and detail through the warehouse reports and real-time data of the WMS system.

In the past: Warehouse suppliers passively received goods, and based on experience, they were put into storage and shelved, leading to frequently used materials being stored deep in the inventory, which reduced the efficiency of returning goods for picking.

Now: Before the arrival of goods from supplier Zhao, the warehouse can check the material progress in real-time through PDA, and scan the barcode through PDA upon arrival, combining material attributes and storage strategies (uniform distribution, first-in first-out, storing commonly used materials near the warehouse location, etc.) to guide the material to the storage location.

In the past: During peak warehouse order periods, pickers would carry dozens of paper picking orders, shuttling back and forth in a warehouse spanning thousands of square meters, repeatedly searching for items. The path was chaotic, requiring significant physical exertion and leading to a high error rate.

Now: Through the WMS system, orders are automatically aggregated. Using intelligent picking and path optimization algorithms, multiple orders are merged, and optimal picking paths are planned for the warehouse. This guides the pickers to pick goods according to the warehouse area, reducing duplicate routes and picking actions. As a result, the picking efficiency has increased by over 50%, and the accuracy rate is close to 100%.

In the past: From the warehouse to the production line, materials were delivered to the production line by manual labor or forklifts. The delivery route was determined by location codes recorded on paper sheets, relying on mental memory.

Now: Through the integration of the WMS system with the automated warehouse and AGV system, combined with production planning and wave consolidation, automatic scheduling of off-shelf operations in the automated warehouse and AGV distribution is achieved. The automatic planning system automatically disassembles distribution time slots based on various strategies such as time slots/time sequences/passing points, and schedules AGVs for real-time distribution, freeing up manpower.

1883D6D19D79454E9B3FA44C8F7F50F7.png)