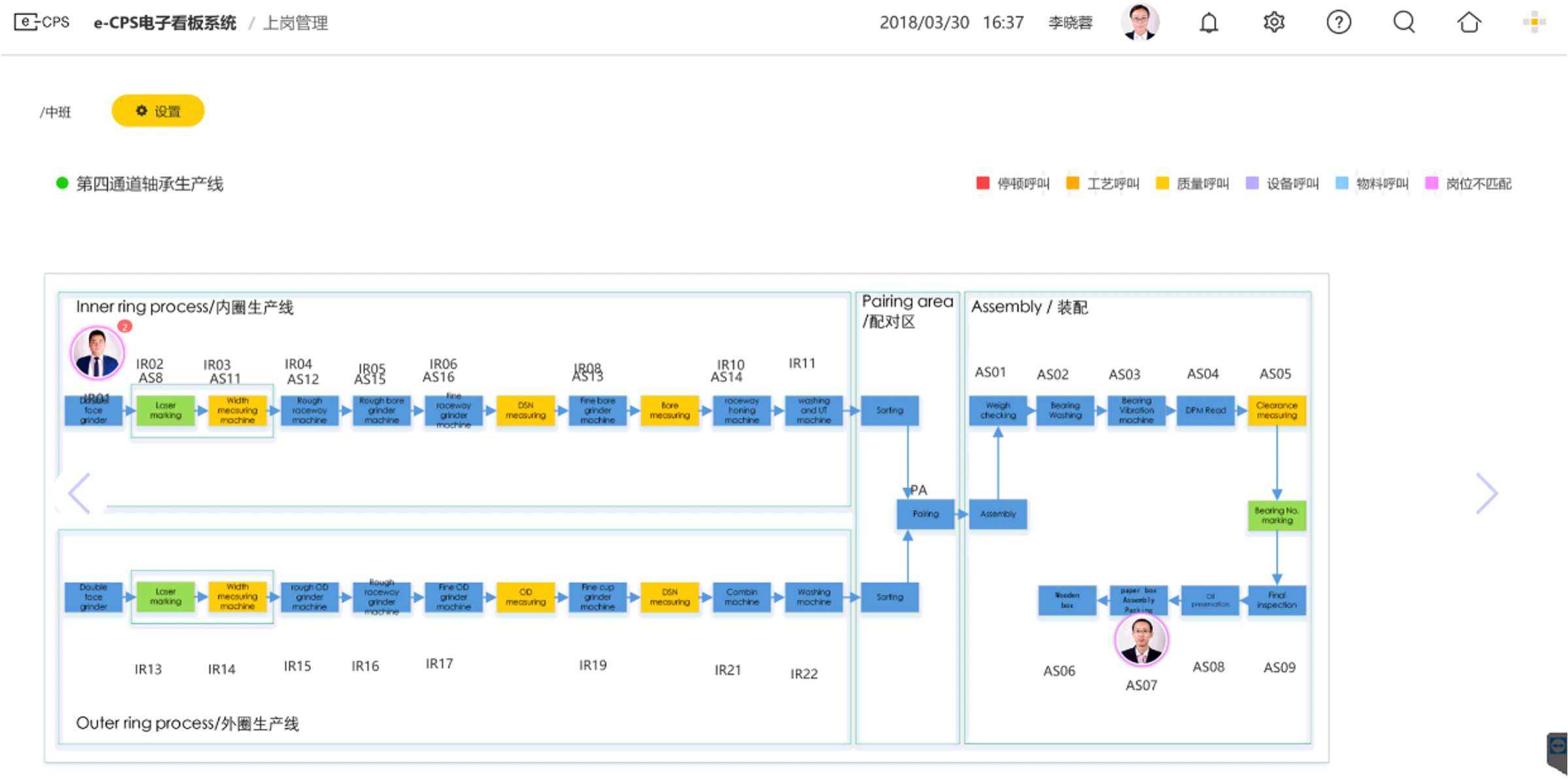

EOS management and operation platform, realizing production data monitoring and task kanban for production workshop teams.

Business requirements such as shift handover records, team meetings, and safety training.

Assist team leaders in achieving point-to-point dispatching and task tracking.

Historical tracing of safety, production downtime, defect analysis, and other issues.

Present and save through intelligent methods such as big data analysis and cloud computing.

Ensure the continuity of factory production and maximize efficiency.

Production personnel: sign in, tasks, job reporting, Andon call, messaging, rationalization suggestions, learning.

Team leader: Dispatch, performance, shift handover, suggestion tracking, accident reporting.

Workshop Manager: Safety, Quality, Delivery Efficiency, Cost, Team, Environment.

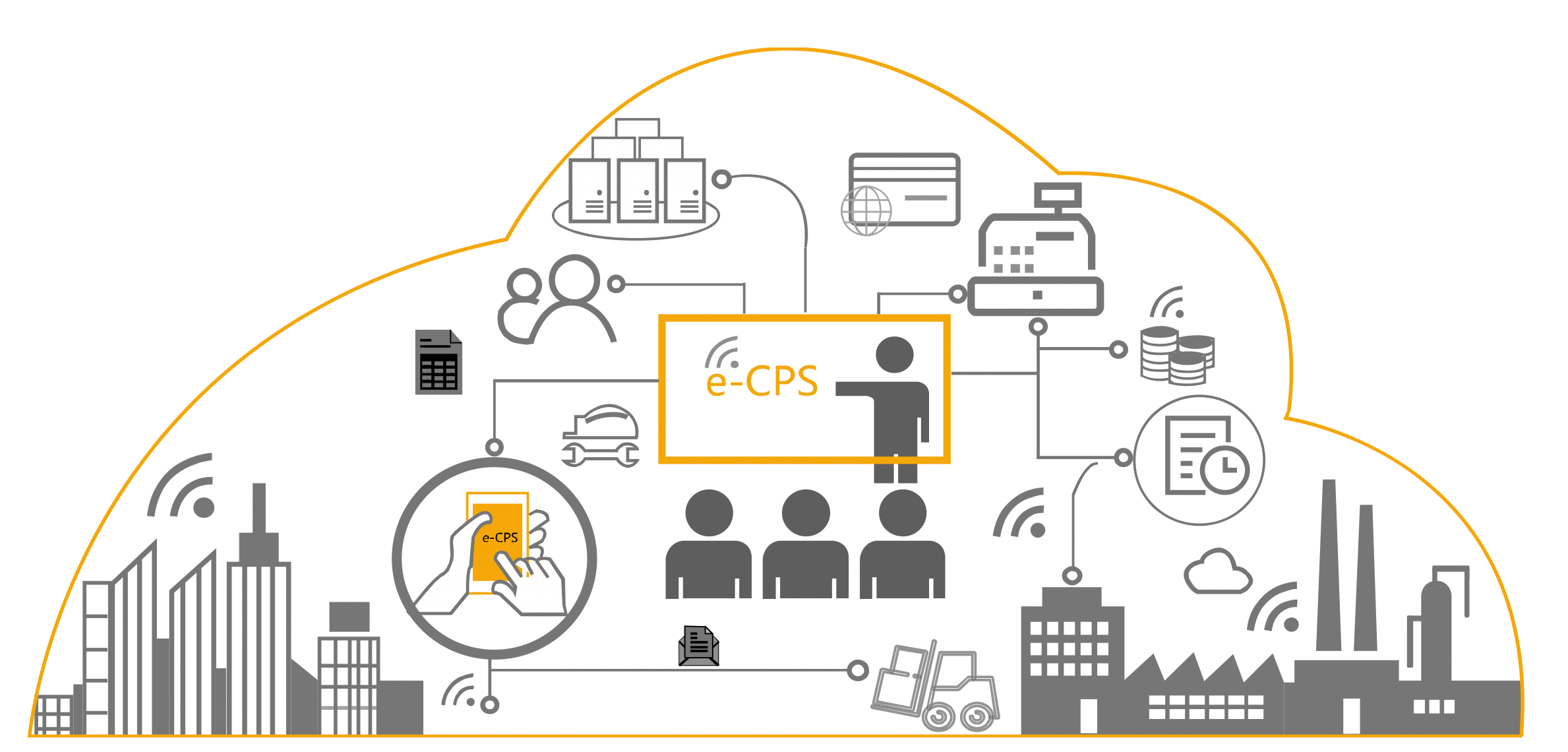

Seamless connection with MES, PDM, ERP, and APP.

Realize basic information collaboration, material requirement collaboration, and order delivery collaboration in enterprise production workshops.

Supervise safety, quality, and cost-effectiveness effectively, reduce costs, optimize manpower, and improve efficiency.

Relying on the SAAS platform, integrating cloud computing and big data analysis.

An intelligent system that integrates mobile intelligent terminal devices.

Realize interaction with physical processes through human-computer interaction.

Realize remote, reliable, real-time, secure, and collaborative data-driven management and intelligent analysis.

Meet the real-time control of workshop production dynamics and achieve transparent management of the enterprise.

Implemented human-computer interaction, simplified operations, and data analysis.

Integrating functions such as mobile internet and peer-to-peer information communication.

Realize real-time communication of personnel, equipment, and information, and achieve agile response to things.

1883D6D19D79454E9B3FA44C8F7F50F7.png)